rockwell hardness test scales|rockwell hardness c scale chart : purchasers There are several alternative scales, the most commonly used being the "B" and "C" scales. Both express hardness as an arbitrary See more Resultado da List your business on Google with a free Business Profile (formerly .

{plog:ftitle_list}

Resultado da 26 de dez. de 2023 · Curiosi come siamo, abbiamo cercato di saperne di più su di lui. Il nome di Zeus è in realtà Ilan Tobianah . È nato il 22 novembre .

The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). There are different scales, denoted by a single letter, that use different . See moreThe differential depth hardness measurement was conceived in 1908 by Viennese professor Paul Ludwik in his book Die Kegelprobe (crudely, "the cone test"). The differential-depth method . See moreThe Rockwell hardness test can be conducted on several various hardness testers. All testers, however, fall under one of three categories. Bench model hardness testers can be found . See more

There are several alternative scales, the most commonly used being the "B" and "C" scales. Both express hardness as an arbitrary See more• International (ISO)• US standard (ASTM International) See more• Brinell hardness test• Hardness comparison• Holger F. Struer• Knoop hardness test See more• Video on the Rockwell hardness test• Hardness Conversion Chart• Rockwell to brinell conversion chart• Hardness Conversion Table See more

The equation for the Rockwell hardness test for metals is below: d=depth from zero load point. N and s = various scale factors that can be found in the chart below. Rockwell A scale. Used to test: Tungsten carbide. Rockwell .ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application. The ASTM specifies different Rockwell hardness scales for various combinations of test loads and indenter types. Rockwell scales allow . The Rockwell hardness testing method fulfilled every requirement. After 100 years, it’s still the best metal strength test method. The Rockwell C .

This results in 30 different Rockwell scales standardized according to ISO 6508 and ASTM E18 (e.g., A, B, C, 30N, 15T) or Rockwell test methods (e.g.: HRA, HRBW, HRC, HR30N, HR15TW), each covering different hardness ranges .Rockwell hardness testing and ASTM E18 standards. Hardness is defined as a material’s resistance to permanent indentation. Current Rockwell hardness test methods are specified in ASTM E-18 and anyone wishing to perform a .

The Rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented carbides. This article explains the procedure to perform the .Definition of the Rockwell hardness test method The Rockwell hardness test methods are described by a number of scales, characterized by a standard, an indenter type, and a load. Examples of Rockwell hardness test methods: .testing (e.g., 30 N and 30 T scales). High Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness Testing Like the Brinell, Vickers, Knoop, Scleroscope and Leeb tests - all of which fall in the general category of indentation hardness tests - the .

No wonder, Rockwell hardness testing scales are globally used and are the most popular ones. It is used for static hardness testing of the material. We have described thoroughly in this article the scales of the hardness test. Just follow the standard scale tables and rules to get the accurate values of the hardness of your test material.Rockwell Hardness Number – Rockwell Scale. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload .Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). . Each Rockwell hardness scale .

A widely used variant of the Rockwell hardness test is the superficial Rockwell test, wherein the minor load is 3 N and the major loads are 15, 30, or 45 N.Further details on the Rockwell superficial hardness scales are available in the relevant ASTM standards (ASTM 1984).The Rockwell hardness values are expressed as a combination of hardness number and a scale .

These approximate relationships between hardness and tensile strength do not apply to nonferrous metals, with the possible exception of certain aluminum alloys. Related: Brinell Hardness Testing Equation. Table A Brinell Hardness to Rockwell Hardness Conversion Table The scale follows an even subdivision of 0.002 mm (2 µm), so that reaching half the reference depth also corresponds to half the maximum hardness value (Rockwell hardness value 50). When diamond cones are used, the Rockwell scale is .

A scale indicating the hardness of materials, first used in 1919, when it was invented by Stanley P. Rockwell.The measurement has no units. The symbol is HR followed by a letter indicating one of a number of possible scales, described in the table below.

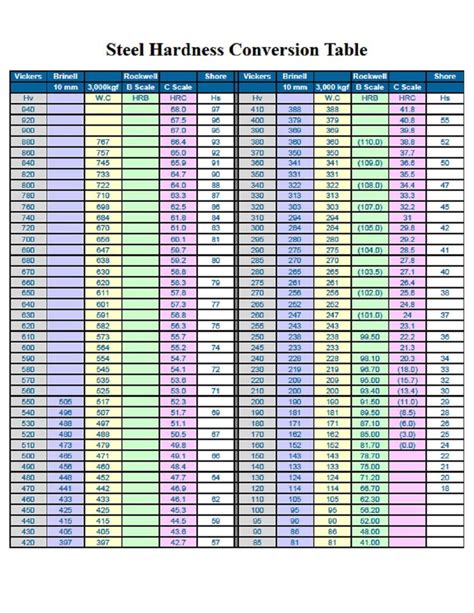

That’s why these standards formulate tables for conversion process, with test load and hardness ranges. Here are the hardness tables and conversion charts for you. . it is a common process to convert one hardness scale to another. For this purpose, many Standards of international level such as ASTM E140, ISO 18265 have converted scales .The ASTM specifies thirty different Rockwell scales, each employing a different combination of test forces and indenter types, which allows the testing Test Procedure of most types of metallic materials and products. When Rockwell hardness is called out by a product standard or specification, the choice of scale is usually specified. In situations where the user must choose .Scale C (carbide) testers are used for testing cemented carbides in the Rockwell A Scale, where tolerances of ± 0.20 of a Rockwell Hardness point are required. A specially selected “A” Brale penetrator is used to measure the hardness of cemented carbides in accordance with ASTM B 294 and the Cemented Carbide Producer’s Association (CCPA).

the test isn't that hard the test meme

In Rockwell hardness testing, HRA, HRB, and HRC represent three different scales: Scale A, Scale B, and Scale C. The Rockwell test is a common indentation hardness test. All three scales begin with an initial pressure of 98.07N (10kgf), and the hardness value is calculated based on the depth of indentation.Principle of Rockwell hardness scale . The Rockwell M hardness test is not valid for plastics that are less than 0.05 inch (1.27 mm) thick. This is because the indenter can penetrate too deeply into thin materials, giving a falsely high hardness reading. Temperature Every Rockwell hardness scale is identified by a letter signifying the indenter type and the two loads used for the test. A Rockwell hardness number is a combination of the numerical hardness value and the letter for .

Hardness scales Hardness according to Rockwell (HRc - cone and HRb - ball) The depth of penetration of an indenter is measured by loading a certain force. Either a ball (HRb) or cone (HRc) can be used. It is a quick and simple . Calculate or convert Rockwell hardness number to different hardness scales using the Rockwell hardness conversion calculator. . The test procedure for the Rockwell hardness test is covered in the standard document ISO 6508 for metallic materials and ISO 2039-2 for plastics. The overall procedure is similar to other indentation tests.While the Rockwell hardness testing scale is prevalent, it is best to consider the material thickness and softness to select the most suitable scale between Rockwell B (HRB) and Rockwell C (HRC). This article compares two types of Rockwell hardness to help you find the most ideal of the two for your hardness testing and conversion needs. Rockwell hardness testing can determine the hardness of most metals, alloys and plastics. . Rockwell Scales . Rockwell hardness values are expressed as a combination of a hardness number and a scale symbol representing the indenter and the minor and major loads. The hardness number is expressed by the symbol HR and the scale designation.

The test must be carried out with a specific type of scale or tester, called a Rockwell hardness scale. How It Works. The hardness test is done through a series of pressure tests. An indenting tool, typically a diamond or ball indenter, presses against the material’s surface.Rockwell hardness testing of plastics is described, and conversion charts correlating various scales are presented. The Rockwell E, M, and R scales of hardness are commonly used for 'hard' polymers such as nylon, polystyrene, acetal, and polycarbonate. Rockwell Hardness Scale. The Rockwell Hardness Scales comprise various types, depending on the material to be tested. Each scale utilizes different loads or indenters, and permits the testing of materials with different hardness. For instance, the HRB scale is employed for testing soft steels, aluminium, and brass, and involves applying minor .

The article helps you understand principle and applications of the Rockwell hardness test method. + 86 755 61301520; [email protected]; Search. Home; About Us. Who We Are; Our History; Why Choose Us; Testing Types. . Material Type – When no hardness scale is specified for a material type, it is often critical to identify the material . For the lowest hardness test force, the 15 Kgf scales, a polished or lapped surface is recommended. . Verification should be performed by an accredited verifying agency and the report should follow and reference ASTM E18 Rockwell test method. Hardness testing is an important and useful tool in materials testing, quality control and acceptance .ix. HRK – The final scale in the Rockwell series of tests, Scale K administers 150 kgf to a steel spherical indenter. This test is frequently applied to materials like plastic, tin, and alloy. Should There Be a Break. A hardness test’s immediate result is that you will eventually get to the material’s breaking point.

In this blog post, you’ll read:Rockwell hardness testing is the most commonly used hardness testing method to measure the permanent depth of an indentation, which is finally compared to the Rockwell scale to derive the hardness number. . In the case of Rockwell Scale, Hardness range comes in two types as mentioned below: High hardness range;

rockwell steel hardness chart

rockwell r scale conversion chart

web16 de jul. de 2021 · Lyrics Amarte Mas No Pude. Diomedes Díaz. Written by: Last update on: July 16, 2021. 1 Translation available. The Lyrics for Amarte Mas No Pude by .

rockwell hardness test scales|rockwell hardness c scale chart